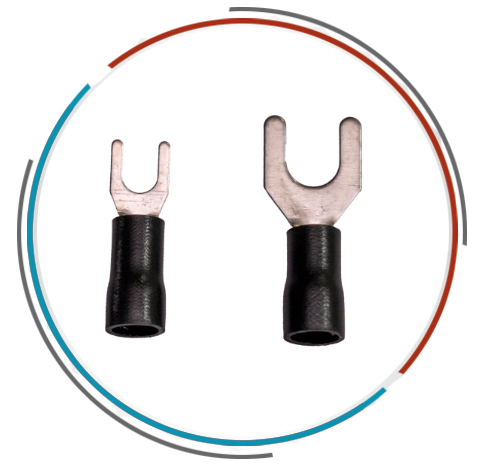

Copper Fork 'U' Type Insulated Terminal

Cordlug stands as a leading manufacturer and supplier of copper lugs renowned for their exceptional quality, specializing in the production of high-grade lugs and terminals. We excel in delivering best quality precision lugs at competitive prices from our manufacturing facility. We take pride in our ability to offer cost effective solutions that meet the requirements of our customers. Our in-house technical expertise provides us with a significant competitive advantage. Stringent quality checks are conducted throughout the manufacturing process, ensuring that only materials meeting rigorous standards are released to the market.

Copper fork "U" type insulated terminals are essential components used in electrical and electronic systems to provide a secure and insulated connection between wires or cables. These terminals are specifically designed with a "U" shape, resembling a fork and are equipped with insulation material to prevent electrical hazards and ensure reliable performance.

These products are made from high quality copper material known for its excellent conductivity and corrosion resistance. The insulation material, often made of heat resistant and durable materials like PVC or nylon, is applied to the terminal to provide electrical insulation and protect against short circuits or accidental contact.

These terminals come in a range of sizes and configurations to suit various wire gauges and connection needs. They are designed with a U- shape, allowing for easy insertion and crimping onto the wire ends. The insulation material is applied to the portion of the terminal that comes into contact with the wire, ensuring a secure and insulated connection.

The insulation on copper fork U- type terminals serves multiple purposes. It helps to prevent electrical shocks and short circuits by providing a barrier between the conductive copper and other conductive surfaces. The insulation also protects against moisture, dust and other environmental factors that could compromise the integrity of the connection.

Proper installation of copper fork U- type insulated terminals is crucial to ensure a reliable and insulated connection. It is important to use the appropriate crimping tools and techniques to achieve a secure and durable connection. The insulation should be properly positioned and secured to prevent any movement or damage.

These terminals find applications in various industries including electrical panels, control systems, automation and telecommunications, aerospace, windmill, solar industry etc.They are commonly used in wiring harnesses, terminal blocks and connectors to provide a safe and reliable connection while maintaining electrical insulation.

Applications :

Electrical Panels : These terminals are commonly used in electrical panels for connecting wires securely. They facilitate the connection of multiple wires to a single terminal point, ensuring efficient distribution of electrical power within the panel.

Automation : In automated manufacturing processes, these products are utilized for wiring control panels, Programmable Logic Controllers, motor controls and other components essential for controlling machinery and equipment. They ensure stable electrical connections to support uninterrupted automation operations.

Telecommunications : Within the telecommunications industry, these terminals are employed in the installation and maintenance of communication equipment such as switches, routers and telecom towers. They help in establishing connections between various communication devices and ensuring smooth data transmission.

Aerospace : In aerospace applications, where reliability and performance are critical, these components are used in aircraft wiring systems. They provide secure connections for electrical components and systems onboard aircraft including lighting, instrumentation and power distribution systems.

Windmill and Solar Industry : These are integral components in wind turbine and solar panel installations. They are used for connecting electrical cables within wind turbine towers and solar panel arrays, ensuring efficient energy transmission from renewable sources to power grids.

The U-type insulated terminal produced at our unit undergoes testing at accredited laboratories (ELCA Laboratories). They are approved by ISO/IEC standards and scrutinized by our in-house professional technical team. These terminal ends are applied in situations where establishing a permanent connection between two cables or devices is unfeasible.